OUR PRODUCTS

OUR SOLUTIONS

Why choose RustX

Rust-X is a Global Market Leader for Corrosion Prevention Products & Solutions and manufactures over 500 products in 45 countries. Rust-X caters to over 10,000 customers in Automotive, Aersospace, Oil&Gas, Infrastructure etc. with its presence in all continents.

Advantages with Rust-X

VCI SMP Technology

VCI SMP (Speedy Moisture Passivation) technology passivates the metal’s surface as well as deactivates the humidity surrounding the metal components. They have sufficient vapour pressure to evaporate and travel to mix with the humidity and essentially reach the surface of the metal. 20% of the VCI Chemical reacts within 6 hours and balance in 5-15 years.

OUR CLIENTS

OEM

AUTO COMPONENTS

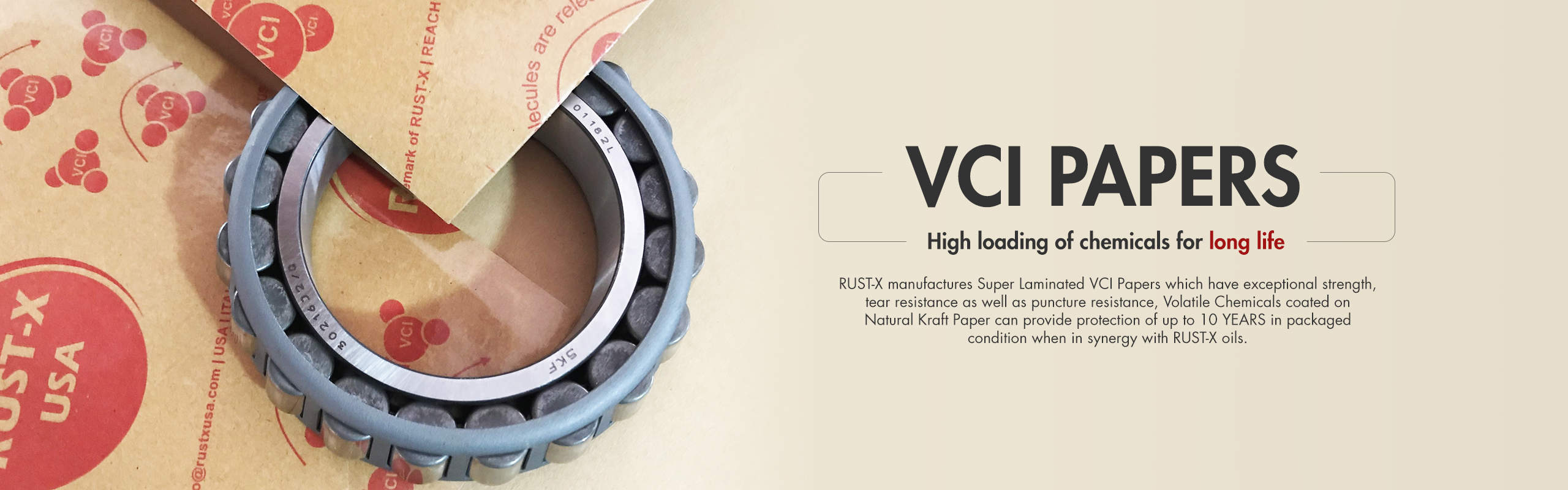

Corrosion Prevention Products

Learn how our Products and Solutions can help you to prevent corrosion and grow your business.

THE REAL VCI Test

Is in your hands, myths of VCI unfolded

The Razor blade test and the VIA test as listed by NACE and BFSV Germany are the only real VCI’s test methods to determine the efficacy of a VCI product.

Rest Without Rust

Rust-X is the only vertically integrated VCI manufacturer in the industry with inhouse manufacturing of chemicals, masterbatch, films, papers, desiccants, oils and foils. This gives the customer an advantage to rely on Rust-x complete packaging solution ensuring them to Rest Without Rust.

Channel Partners

VCI Products

Customers

TIMES NOW 40 UNDER 40

Mr. Mukul Sareen’s Innovative Journey and ’40 under 40′ Recognition

FOLLOW US ON